When it comes to building structures that demand exceptional strength and durability, G550 high-strength steel stands out as a top-tier material. With a tensile strength exceeding 550 MPa —nearly double that of conventional steel—this advanced alloy ensures reliability in high-load applications. Its superior corrosion resistance further enhances longevity, making it a smart investment for long-term projects.

MENU

Optimal Chemical Composition for Maximum Performance

G550 steel boasts a meticulously engineered chemical composition, ensuring both strength and flexibility:

– Iron (98.5%) – The primary component, providing structural integrity.

– Carbon (0.3%) – Enhances hardness without compromising ductility.

– Manganese (0.8%) – Improves toughness and wear resistance.

– Silicon (0.5%) – Strengthens the alloy while maintaining workability.

– Phosphorus & Sulfur (≤0.04% & ≤0.06%) – Kept at minimal levels to prevent brittleness.

This precise balance ensures high load-bearing capacity while retaining the flexibility needed for fabrication.

Versatile Applications Across Industries

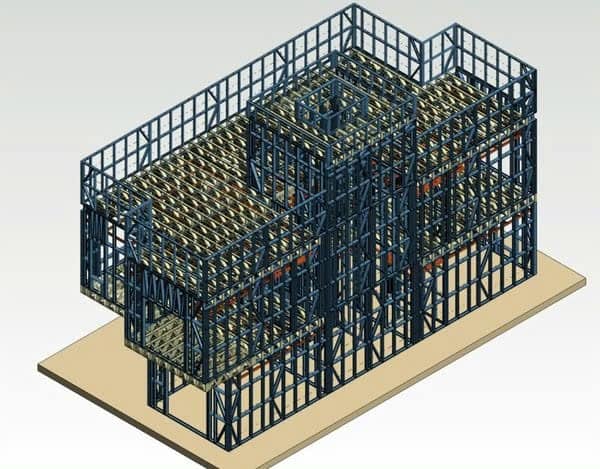

From residential buildings to large-scale industrial projects , G550 steel delivers unmatched performance:

– Construction: Ideal for pre-engineered buildings, bridges, and high-rise steel frames .

– Mechanical Engineering: Perfect for heavy machinery, industrial equipment, and construction tools .

– Transportation: Used in truck chassis, trailers, and shipping containers due to its lightweight yet durable nature.

Why High-Strength Steel G550 Outperforms Traditional Materials

1. Exceptional Strength-to-Weight Ratio – Lighter than conventional steel yet 50% stronger , reducing structural weight without sacrificing stability.

2. Superior Corrosion Resistance – Withstands harsh environments, extending the lifespan of structures.

3. Ease of Fabrication – Can be cut, welded, and shaped efficiently, reducing labor costs.

4. Cost-Effective – Minimizes long-term maintenance expenses due to its durability.

Compliance with International Standards

G550 steel is manufactured under ASTM A572 A572M , ensuring:

– Strict adherence to chemical and mechanical properties .

– Precise dimensional tolerances for consistency.

– Reliable performance in extreme conditions .

How to Choose and Maintain

Pricing Factors:

– Thickness, coil length, surface finish, and supplier reputation.

Buying Tips:

– Verify origin and quality certifications (ISO, ASTM).

– Request material test reports (MTRs) for validation.

Storage & Maintenance:

– Store in a dry, well-ventilated area .

– Avoid direct exposure to corrosive chemicals.

The Future in Construction

As the construction industry shifts toward lighter, more sustainable materials , G550 steel is leading the charge. Innovations like hot-dip galvanizing are further enhancing its resistance to extreme conditions, making it ideal for:

– Green buildings & smart infrastructure.

– Seismic-resistant structures.

– Offshore and marine applications.

Choosing a Reliable Supplier

To ensure quality, partner with suppliers that offer:

– ISO 9001 & ASTM A572 certifications.

– In-house production facilities.

– Technical support for project-specific needs.

Final Thoughts

G550 high-strength steel is revolutionizing modern construction and engineering . Its unmatched durability, lightweight properties, and corrosion resistance make it the go-to material for builders and engineers worldwide. Whether for industrial plants, bridges, or machinery , G550 steel guarantees long-lasting performance and cost efficiency .

Looking Ahead: Advanced Applications

As technology evolves, G550 steel is being adapted for even more demanding uses:

1. Modular and Prefabricated Construction

With the rise of modular housing and rapid-build solutions , G550’s lightweight yet sturdy nature makes it perfect for prefabricated wall panels, roofing, and framing systems . Its ease of assembly reduces construction time by up to 40% , making it ideal for disaster relief housing and urban development projects .

2. Renewable Energy Infrastructure

Wind turbines, solar panel mounts, and hydroelectric plants require materials that can endure extreme weather and heavy loads . G550 steel’s high fatigue resistance ensures reliability in offshore wind farms and solar installations , contributing to sustainable energy solutions .

3. Automotive and Aerospace Innovations

The automotive industry is increasingly using high-strength steel to improve fuel efficiency without compromising safety . G550’s crash-resistant properties make it suitable for vehicle frames and roll cages . Meanwhile, in aerospace , research is exploring its use in lightweight aircraft components .

4. Smart Cities and Infrastructure

As cities embrace smart technology , G550 steel supports adaptive infrastructure , such as retractable roofs, movable bridges, and dynamic facades . Its flexibility and strength enable innovative architectural designs that were previously unfeasible.

Conclusion: Why G550 is the Material of Tomorrow

From skyscrapers to sustainable energy , G550 high-strength steel is proving indispensable. Its unrivaled durability, cost-efficiency, and adaptability ensure it will remain a cornerstone of modern engineering . For builders, architects, and engineers , adopting G550 means future-proofing projects while maximizing performance.

Ready to upgrade your next project with G550 steel? Partner with certified suppliers and experience the next generation of construction materials.