PN Steel delves into whether light gauge steel framing stands as the most advanced material in the offsite construction technology portfolio. We explore the challenges associated with utilizing these frames and highlight their properties and advantages compared to alternative materials.

This article examines the properties and benefits of light gauge steel frames in comparison to other materials commonly used in offsite construction technologies. It will explore how these frames contribute to reducing project timelines from concept to completion while addressing challenges such as cost, transportability, and weight considerations. Finally, the article evaluates whether alternative products or services may offer greater advantages over light gauge steel frames in the realm of offsite technologies.

MENU

What are the benefits of offsite technology?

Offsite technology has rapidly gained traction in the construction industry, thanks to its cost efficiency, reduced environmental impact, and integration of smart technologies. This innovative approach to prefabrication has transformed the way buildings are designed and constructed, enabling more efficient use of both materials and labor. Compared to traditional on-site methods, offsite technology offers significant advantages, including faster production rates and reduced waste.

The integration of smart technologies further elevates the efficiency and performance of offsite systems. Automated processes ensure components are manufactured quickly and with precision, minimizing errors caused by manual data entry or design modifications. These advanced systems also streamline assembly processes, cutting down on-site labor requirements and accelerating project timelines. Additionally, sophisticated software solutions track inventory levels throughout the construction process, providing enhanced control over budgeting and resource management.

Light gauge steel is durable, cost-effective and versatile

Light gauge steel has emerged as a favored material in modern construction due to its durability, cost-effectiveness, and adaptability. Widely used in offsite technology applications such as modular building systems and prefabricated components, it offers a compelling combination of benefits. However, the question persists: is light gauge steel truly the most advanced material available in the offsite construction technology landscape today?

To address this, it is essential to understand what sets light gauge steel apart. Unlike traditional steel construction, light gauge steel consists of thin sheets of galvanized or cold-rolled steel, precision-cut into pre-determined lengths by automated machinery. These sheets are shaped and assembled using bolts or rivets, resulting in lightweight yet robust frames suitable for various structures, including residential homes, commercial buildings, and industrial facilities.

When compared to heavier structural members made from hot-rolled steel sections, light gauge steel offers several distinct advantages. Its lightweight nature simplifies transportation and handling, reducing logistical challenges. Additionally, it is typically more cost-effective, making it an appealing option for budget-conscious projects. Another significant advantage is its installation process: light gauge steel frames do not require welding, which not only mitigates fire hazards but also minimizes the risk of errors during assembly. This makes it particularly advantageous for high-rise construction, where safety and precision are critical.

While light gauge steel may not encompass every technical innovation available in the offsite construction materials portfolio, its balance of strength, affordability, and ease of use makes it a standout choice for a wide range of projects. From small-scale builds to large commercial developments, its versatility continues to reinforce its position as a cornerstone material in modern construction.

Advantages of Using Light Gauge Steel Framing

Light gauge steel framing offers numerous benefits that make it a preferred choice for architects and builders over traditional stick-framing or other conventional materials like timber and concrete blockwork. Its advantages span cost efficiency, strength, flexibility, and performance, making it an excellent option for modern construction projects.

-

Cost Savings

Light gauge steel framing is more cost-effective than traditional stick-framing, primarily due to reduced labor requirements and faster assembly times. The prefabricated components are designed for quick and easy installation on-site, which significantly lowers construction time and labor expenses. -

Strength and Durability

One of the standout features of light gauge steel is its exceptional strength. The metal components are engineered to be incredibly tough and stable, allowing them to withstand heavy loads with minimal deformation over time. This durability ensures a longer lifespan compared to other materials. -

Design Flexibility

Light gauge steel provides enhanced design flexibility, enabling architects to create intricate and complex structures without compromising strength. Its adaptability makes it suitable for a wide range of construction projects, from residential homes to commercial buildings. -

Low Maintenance

Unlike timber or other materials prone to issues like rot, warping, or pest infestation, light gauge steel requires minimal maintenance. This long-term reliability reduces the need for ongoing repairs, offering additional cost savings. -

Thermal Insulation

Light gauge steel frames offer excellent thermal insulation due to their airtight properties. They minimize heat transfer, ensuring stable internal temperatures and enhancing energy efficiency throughout different seasons. -

Acoustic Performance

The frames provide superior acoustic insulation, making them ideal for areas where noise reduction is essential, such as residential neighborhoods or commercial spaces near high-traffic zones.

In summary, light gauge steel framing combines strength, efficiency, and performance with cost and time advantages, making it a versatile and practical solution for various construction needs. Its ability to meet structural and environmental requirements positions it as a forward-thinking choice in modern construction practices.

Types of Steel Used in Construction

Steel is a versatile material used in construction for its strength, durability, and adaptability. The type of steel chosen depends on the specific requirements of the project. Here are some of the most common types of steel used in the construction industry:

-

Cold-Rolled Steel

Cold-rolled steel is widely used due to its excellent formability and strength. It is often galvanized to protect against corrosion, making it a reliable option for structural framing and other applications where precision and resistance to rust are essential. Its ability to be bent or shaped into complex forms makes it ideal for offsite construction. -

Galvanized Steel

Galvanized steel is coated with a layer of zinc to prevent corrosion and rust, making it particularly suitable for outdoor and industrial applications. It is commonly used for roofing, cladding, and structural components in environments where durability and resistance to weather are critical. -

Stainless Steel

Known for its superior strength, corrosion resistance, and durability, stainless steel is a premium material used in offsite construction projects requiring high-performance materials. Its sleek, polished finish also makes it a popular choice for architectural features and interior designs. -

Alloy Steel

Alloy steel combines iron with other elements like chromium, nickel, or molybdenum to enhance mechanical properties such as strength, toughness, and wear resistance. It is used in applications where superior performance is needed, such as in high-stress or load-bearing structures. -

Corten Steel

Corten steel, also known as weathering steel, develops a unique patina when exposed to the elements over time. This rust-like finish acts as a protective layer, eliminating the need for painting or additional coatings. Corten steel is often chosen for its aesthetic appeal in architectural projects and decorative facades.

Steel in Offsite Technology

Offsite construction projects make use of these steel types based on their specific characteristics:

- Cold-rolled steel provides exceptional formability for precise manufacturing of modular components.

- Stainless steel ensures durability and corrosion resistance in harsh environments.

- Alloy steel meets demands for enhanced strength and performance in high-stress applications.

- Corten steel offers a decorative touch with its evolving patina, making it ideal for design-focused projects.

Each type of steel plays a critical role in modern construction, offering tailored solutions to meet the diverse needs of offsite and on-site building technologies.

Comparing Light Gauge Steel to Other Building Materials

When compared to materials like wood, concrete, prefabricated panels, structural insulated panels (SIPs), and masonry, light gauge steel (LGS) offers distinct advantages and some limitations:

Advantages

Strength and Durability:

Light gauge steel is preferred by 22% of builders for its superior strength and durability. Its resistance to pests, warping, and shrinkage gives it an edge over materials like wood.Design Flexibility:

Architects favor light gauge steel for its adaptability, allowing the creation of complex and unique designs with ease.Efficiency:

LGS is lightweight and can be produced quickly and cost-effectively, making it ideal for smaller structures and modular construction.Compatibility with Lightweight Sheathing:

Frames can incorporate materials like aluminum or plastic sheathing, which reduces weight and enhances energy efficiency.

Disadvantages

Maintenance and Corrosion Risks:

LGS may require more maintenance than traditional materials and is susceptible to corrosion when exposed to moisture over time.Installation Challenges:

Incorrect installation or the use of substandard materials can lead to premature deterioration.Insulation Performance:

While LGS provides decent insulation against sound and heat, it does not match the superior insulation properties of SIPs or masonry.

Technical Specifications and Requirements for Light Gauge Steel Framing

To ensure the safe and effective use of light gauge steel, strict technical standards and specifications must be followed:

Steel Grades

- Commonly used grades include cold-rolled structural steels with yield strengths ranging from 250 MPa to 550 MPa.

Framing Components

- Standard components include:

- Studs, joists, trusses, purlins, rafters, and braces.

- Fittings such as nuts, bolts, screws, and fasteners tailored to specific structural needs.

Installation Requirements

- Foundation Depth:

Determined by soil conditions to ensure stability. - Wall Spacing:

Must adhere to Australian Standards (AS 1684) or equivalent. - Fire Ratings:

Walls and ceilings must comply with AS 1530 Part 4:2014 for fire resistance. - Fastening Schedules:

Installers should follow AS 3566:2015, specifying appropriate fasteners for structural connections. - Insulation Values:

Thermal and acoustic performance must meet standards outlined in AS/NZS 4859 series.

By adhering to these specifications, light gauge steel framing ensures structural integrity, safety, and compliance with regulatory requirements, making it a reliable choice for modern construction projects.

Technical Specifications and Requirements for Light Gauge Steel Framing

Light gauge steel framing (LGSF) requires adherence to strict technical specifications and standards to ensure safety, structural integrity, and efficiency. These requirements cover the materials used, components, and installation processes.

Steel Grades

- Light gauge steel is typically manufactured from cold-rolled structural steels with yield strengths ranging between 250 MPa and 550 MPa.

- These high-strength steels ensure durability and reliability in various construction environments.

Framing Components

- Commonly used components include:

- Studs

- Joists

- Trusses

- Purlins

- Rafters

- Braces

- Associated fittings include nuts, bolts, and screws designed to securely fasten the frame elements.

Installation Requirements

Installation standards vary depending on the type of building and region-specific regulations but generally include:

- Foundation Depth:

Determined based on soil conditions to provide stable support for the structure. - Wall Spacing:

Must comply with Australian Standards (AS 1684) or equivalent international standards. - Fire Ratings:

Walls and ceilings must meet the requirements of AS 1530 Part 4:2014, ensuring adequate fire resistance. - Fastening Schedules:

All connections must follow guidelines in AS 3566:2015, which specify fastener types and configurations. - Insulation Standards:

Thermal and acoustic insulation values should conform to the AS/NZS 4859 series for energy efficiency and occupant comfort.

Quality Assurance Methods for Light Gauge Steel Framing

The saying “A stitch in time saves nine” highlights the importance of quality assurance (QA) in light gauge steel framing. QA methods are critical to maintaining the safety and durability of steel frames, ensuring compliance with required standards and minimizing potential issues during or after construction.

Common QA Methods

Measurement Verification:

- All components should be measured against design drawings or blueprints to ensure precise dimensions.

- Accurate cutting is essential as even minor deviations can impact the assembly and structural integrity of the frame.

Visual Inspections:

- Regular inspections during fabrication and assembly ensure that all connections, including welds and fasteners, are secure and free from defects.

- Components should also be checked for signs of rust or environmental damage before use.

Strength Testing:

- Load-bearing tests and structural evaluations should be conducted at various stages to verify the frame’s strength and detect weaknesses.

Environmental Resistance Checks:

- Frames should be tested to withstand potential environmental challenges like moisture, corrosion, or extreme temperatures.

Maintenance Practices for Long-Term Performance

Even after installation, regular maintenance is crucial to preserve the frame’s structural integrity:

Routine Inspections:

Check for signs of corrosion, wear, or other damage and address issues promptly to avoid costly repairs.Protective Coatings:

Ensure the steel is appropriately galvanized or treated to prevent rust and extend its lifespan.

By implementing these QA measures and maintenance practices, light gauge steel framing systems deliver consistent performance, safety, and durability throughout their lifecycle.

Environmental Impact of Light Gauge Steel Framing

As sustainability becomes a cornerstone of modern construction, light gauge steel framing (LGSF) is gaining recognition as an environmentally friendly alternative to traditional materials. Its unique properties make it a viable choice for both residential and commercial projects, aligning with green building priorities.

Key Environmental Benefits

1. High Recyclability

- Steel is one of the most recycled materials globally, and light gauge steel is no exception.

- Recycling steel significantly reduces the energy required for producing new materials, minimizing carbon emissions during manufacturing.

- Reuse of steel components further extends their lifecycle, contributing to resource conservation.

2. Minimal Waste Generation

- Light gauge steel frames are fabricated from thin sheets that are precision-cut to exact specifications.

- This process results in less material waste compared to traditional wood framing, where off-cuts and defects are common.

3. Thermal Efficiency

- Light gauge steel’s unique design creates air pockets within its structure.

- These pockets can be filled with insulating materials like foam, enhancing thermal efficiency and reducing energy consumption for heating and cooling.

- Compared to concrete or masonry, steel frames allow for better integration of advanced insulation systems, further improving energy performance.

4. Reduced Resource Usage

- Steel frames are lightweight, requiring fewer resources for transportation and minimizing fuel consumption.

- Their durability reduces the need for frequent repairs or replacements, leading to long-term environmental savings.

Extended Lifespan and Lower Costs

Buildings constructed with light gauge steel often last longer due to the material’s resistance to pests, fire, and environmental wear. This durability results in:

- Lower maintenance costs over the structure’s lifetime.

- Reduced demand for additional resources, supporting sustainability goals.

Design and Flexibility

Light gauge steel supports a wide range of finishes and design possibilities, offering architects the freedom to create innovative structures without sacrificing sustainability. Its adaptability enables construction of energy-efficient buildings that comply with green building certifications.

Conclusion

Light gauge steel framing not only aligns with the environmental priorities of the modern construction industry but also delivers practical benefits such as recyclability, waste reduction, and energy efficiency. By choosing LGSF, builders and architects can achieve sustainability goals while maintaining cost-effectiveness and durability, making it a cornerstone material for eco-friendly construction.

Design Considerations When Using Light Gauge Steel Framing

The integration of light gauge steel framing (LGSF) into construction projects requires careful planning to ensure both design flexibility and structural integrity. When choosing this material for offsite technology, several important design considerations must be addressed to optimize its use.

1. Building Regulations Compliance

- Building Standards: Light gauge steel framing must adhere to local building regulations and codes. Compliance ensures the structure meets safety standards for both occupants and environmental conditions.

- Fire Resistance: Steel’s non-combustible nature helps meet fire safety requirements, especially in high-rise or multi-use buildings.

- Seismic and Wind Resistance: Steel’s strength helps it perform well in areas prone to earthquakes or high winds, providing stability even under extreme conditions.

2. Design Flexibility

- Versatility in Design: Thanks to its high strength-to-weight ratio, light gauge steel allows architects to experiment with complex shapes, offering greater creative freedom than traditional materials like wood or concrete.

- Customizability: Steel can be easily molded and cut into precise shapes, allowing for highly customized designs while maintaining structural integrity.

- Ease of Installation: Light gauge steel frames are pre-engineered, allowing for faster assembly and reducing onsite labor time, which is ideal for complex designs requiring quick turnaround.

3. Load-Bearing Capacity

- Strength for Heavy Loads: Light gauge steel is known for its high load-bearing capacity relative to its weight, making it an excellent choice for large-scale projects, such as multi-storey buildings, commercial spaces, or high-rise constructions.

- Structural Stability: The material’s durability and stability under load make it suitable for structures requiring long spans without the need for additional support columns.

4. Other Considerations

- Corrosion Resistance: Steel frames are often galvanized or treated with coatings to prevent rust, especially when exposed to moisture or harsh weather conditions. Ensuring proper protective measures are in place is crucial to maintaining the longevity of the steel.

- Insulation and Acoustic Performance: While light gauge steel is excellent for structural integrity, careful attention must be paid to its insulation properties. Additional materials, such as foam or mineral wool, are often added to enhance thermal and acoustic performance.

Challenges in Producing and Installing Light Gauge Steel Framing

While light gauge steel framing (LGSF) offers numerous benefits, its production and installation present some challenges that must be addressed to ensure efficient and safe implementation.

1. Production Challenges

- Specialized Machinery and Expertise: Producing light gauge steel involves complex processes, including cutting, bending, forming, and welding steel sheets. This requires specialized machinery and highly skilled labor to ensure that components are produced to precise specifications.

- Compliance with Industry Standards: To ensure safety and performance, production must meet various industry standards and regulations, which can add to the complexity and cost.

- Cost of Materials and Labor: The production process is more expensive compared to traditional materials like wood due to the need for specialized labor and machinery, as well as the cost of high-quality steel.

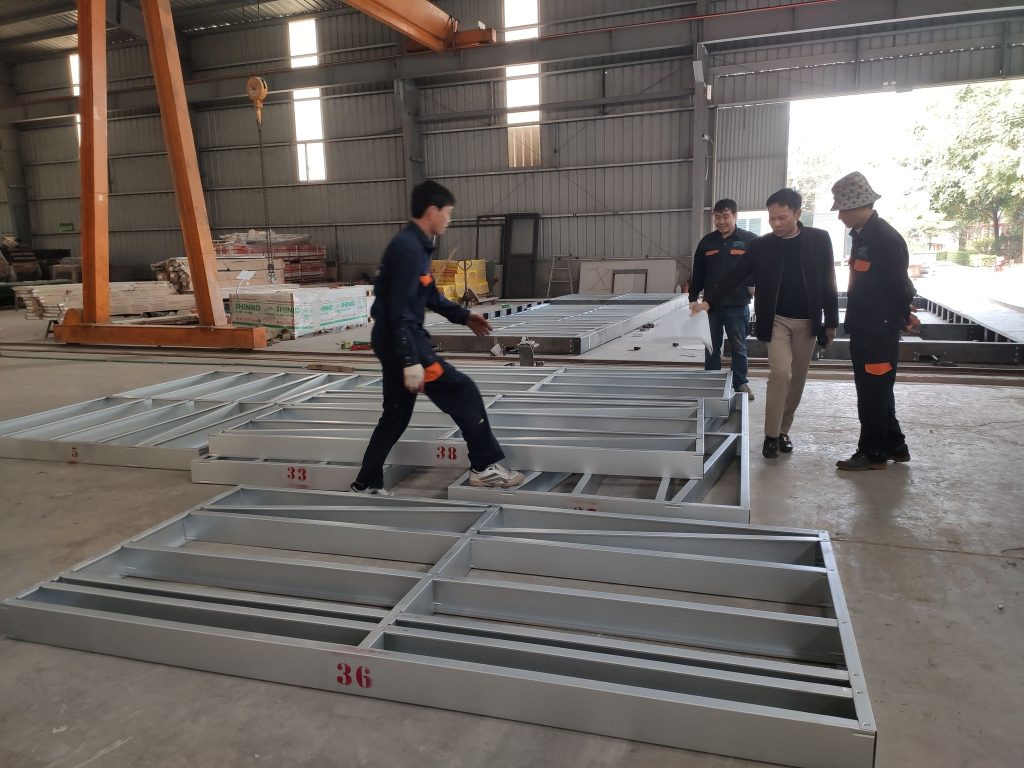

2. Installation Challenges

- Heavy and Large Components: Despite being lightweight relative to traditional steel, light gauge steel frames still require specialized lifting equipment for transportation and installation on-site due to their size.

- Handling and Maneuvering: The components can be cumbersome, and careful handling is necessary to avoid damage during transport and assembly.

- Installation Errors: Even small mistakes during installation can lead to significant structural issues, as light gauge steel requires precise alignment to ensure the integrity of the frame. Incorrectly installed frames can compromise the entire structure, leading to safety hazards.

- Need for Skilled Installers: To mitigate the risk of errors, proper training for installers is essential. Skilled professionals are needed to follow installation guidelines, ensuring that the structure meets the required specifications.

Cost-Effectiveness of Light Gauge Steel Framing

While the cost-effectiveness of light gauge steel framing can be challenging to measure directly, several factors contribute to its potential savings in comparison to traditional construction methods.

1. Reduced Labor and Time

- The precision manufacturing of light gauge steel components reduces labor costs by minimizing errors and streamlining assembly.

- Since the components are pre-fabricated and designed for quick assembly, construction time is significantly reduced, leading to further cost savings.

2. Durability and Longevity

- Light gauge steel is known for its durability and ability to withstand wear and tear better than many other construction materials.

- The longevity of the frame reduces the need for frequent repairs or replacements, contributing to long-term cost savings.

- Additionally, the precision in fabrication reduces errors during installation, leading to a stronger and more stable structure, which decreases the likelihood of costly repairs down the line.

3. Long-Term Financial Benefits

- Although the initial investment for light gauge steel framing can be higher, its low maintenance needs and high durability offer substantial financial benefits over the lifespan of the building.

- The material’s ability to resist environmental factors such as pests, fire, and moisture adds to its long-term value, making it a cost-effective choice in the long run.