In the ever-evolving world of construction, innovation is key to meeting the demands of modern architecture, sustainability, and efficiency. One such innovation that has gained global recognition is Lightweight Steel Framing (LSF) . This advanced building method utilizes cold-formed, galvanized steel profiles with a thin thickness (around 1mm) and lightweight properties. LSF has revolutionized the construction industry, offering a durable, eco-friendly, and cost-effective alternative to traditional building methods.

MENU

The Origins of Lightweight Steel Framing LSF: A Historical Perspective

Lightweight Steel Framing LSF traces its roots back to the early 20th century when engineers sought to replicate the popular wood-framing construction method, widely used in the United States at the time. However, wood framing came with significant drawbacks, such as susceptibility to fire, termites, and moisture damage. Lightweight Steel Framing LSF emerged as a superior solution, addressing these issues while introducing enhanced mechanical strength, making it ideal for harsh weather conditions like storms and tornadoes.

The first Lightweight Steel Framing LSF homes were showcased at the 1933 Chicago World’s Fair, where they were hailed as the “Homes of the Future.” This marked the beginning of a new era in construction, one that prioritized durability, efficiency, and sustainability.

The Rise of LSF Post-World War II

The aftermath of World War II saw an urgent need for rapid reconstruction in countries like Germany, France, and Japan. Coupled with rising environmental concerns, increasing timber costs, and wartime steel expertise, Lightweight Steel Framing LSF gained momentum as a preferred building method. Its ability to be mass-produced and prefabricated made it an ideal choice for large-scale projects, paving the way for its widespread adoption in residential, commercial, and industrial construction.

Today, Lightweight Steel Framing LSF is a cornerstone of modern construction. According to the Steel Framing Industry Association (SFIA), 30-35% of non-residential buildings in the U.S. are constructed using Lightweight Steel Framing LSF structural and non-structural components. Additionally, the Steel Framing Alliance (SFA) reported that 81% of interior partition walls in the U.S. were built using LSF in 2004.

Lightweight Steel Framing LSF in Portugal and Beyond

While traditional concrete and brick construction still dominate in countries like Portugal, Lightweight Steel Framing LSF is steadily gaining traction. The global economic crisis of the late 2000s forced many construction companies to seek innovative solutions, and Lightweight Steel Framing LSF emerged as a game-changer. Its benefits—cost efficiency, rapid construction, high performance, and superior quality control—have made it a viable option for both new builds and renovations.

Moreover, Lightweight Steel Framing LSF’s lightweight and prefabricated nature make it an excellent candidate for export to countries with high housing demands but limited resources for traditional construction methods. For instance, several African nations are exploring Lightweight Steel Framing LSF as a sustainable solution to their housing challenges.

Key Benefits of Lightweight Steel Framing LSF

1. Cost Efficiency : Lightweight Steel Framing LSF reduces material and labor costs, making it an economical choice for builders and homeowners alike.

2. Rapid Construction : Prefabrication allows for faster project completion, saving time and resources.

3. Durability : Lightweight Steel Framing LSF structures are highly resistant to extreme weather conditions, ensuring long-lasting performance.

4. Eco-Friendliness : By minimizing the use of timber and other natural resources, Lightweight Steel Framing LSF contributes to environmental conservation.

The Future of Lightweight Steel Framing LSF

As the construction industry continues to prioritize sustainability and efficiency, LSF is poised to play a pivotal role. Its lightweight, prefabricated design makes it ideal for renovation projects and export to regions with urgent housing needs. With its proven track record and numerous advantages, LSF is not just a modern building solution—it’s a step toward a more sustainable and resilient future.

In conclusion, Lightweight Steel Framing (LSF) represents a transformative approach to construction. By combining durability, cost-effectiveness, and environmental benefits, Lightweight Steel Framing LSF is redefining how we build for tomorrow. Whether you’re constructing a home, a commercial space, or an industrial facility, LSF offers a reliable and forward-thinking solution that meets the demands of today’s world.

Expanding the Reach of Lightweight Steel Framing (LSF)

As the global population continues to grow, the demand for affordable, sustainable, and quickly deployable housing solutions is more pressing than ever. Lightweight Steel Framing LSF is uniquely positioned to address these challenges, particularly in developing regions where traditional construction methods are often too slow, costly, or resource-intensive. For example, in African nations facing rapid urbanization and housing shortages, Lightweight Steel Framing LSF offers a scalable and efficient alternative. Its prefabricated components can be easily transported and assembled, even in remote or resource-limited areas, making it a practical solution for addressing urgent housing needs.

Innovations Driving LSF Adoption

Technological advancements are further enhancing the appeal of LSF. Modern software for design and engineering allows for precise customization, ensuring that LSF structures meet specific project requirements while minimizing waste. Additionally, the integration of energy-efficient materials and smart building technologies into Lightweight Steel Framing LSF systems is paving the way for greener, more sustainable construction practices. These innovations not only improve the performance of Lightweight Steel Framing LSF buildings but also align with global efforts to reduce carbon footprints and promote environmental stewardship.

Challenges and Opportunities

Despite its many advantages, the widespread adoption of LSF is not without challenges. In regions where traditional construction methods are deeply ingrained, shifting to Lightweight Steel Framing LSF requires education, training, and a willingness to embrace new technologies. However, these challenges also present opportunities for collaboration between governments, construction firms, and educational institutions to promote Lightweight Steel Framing LSF as a viable and forward-thinking solution.

A Sustainable Future with LSF

Looking ahead, Lightweight Steel Framing LSF is set to play a crucial role in shaping the future of construction. Its adaptability, efficiency, and environmental benefits make it an ideal choice for a wide range of applications, from residential homes to large-scale commercial and industrial projects. As the world continues to prioritize sustainability and resilience, Lightweight Steel Framing LSF stands out as a building method that not only meets today’s needs but also anticipates the challenges of tomorrow.

Lightweight Steel Framing (LSF) is more than just a construction technique—it’s a testament to human ingenuity and our ability to innovate in the face of evolving challenges. By embracing LSF, we can build structures that are not only durable and cost-effective but also environmentally responsible. Whether you’re a homeowner, builder, or policymaker, Lightweight Steel Framing LSF offers a compelling solution for creating a better, more sustainable built environment. As we move forward, Lightweight Steel Framing LSF will undoubtedly remain at the forefront of construction innovation, helping to shape a brighter future for generations to come.

Global Success Stories of LSF Implementation

Across the globe, Lightweight Steel Framing LSF has already proven its worth in a variety of projects, from residential homes to large-scale commercial developments. In Australia, for instance, LSF has become a popular choice for constructing energy-efficient homes that withstand the country’s harsh climate conditions. Similarly, in Europe, countries like the UK and Germany have embraced LSF for its ability to meet stringent energy efficiency standards and reduce construction timelines.

In disaster-prone regions, LSF has also demonstrated its resilience. After natural disasters such as hurricanes or earthquakes, LSF structures have been used for rapid rebuilding efforts due to their durability and ease of assembly. This adaptability makes LSF not only a practical choice for everyday construction but also a critical tool in disaster recovery and emergency housing.

LSF and the Circular Economy

One of the most exciting aspects of LSF is its alignment with the principles of the circular economy. Steel, the primary material used in LSF, is 100% recyclable, meaning that LSF structures can be dismantled and repurposed at the end of their lifecycle. This reduces construction waste and promotes a more sustainable approach to building. Additionally, the precision of LSF manufacturing minimizes material waste during construction, further enhancing its environmental credentials.

Collaboration and Education: Keys to LSF’s Future

For LSF to reach its full potential, collaboration across industries and sectors is essential. Governments can play a role by incentivizing sustainable building practices and updating construction codes to accommodate modern methods like LSF. Educational institutions can contribute by incorporating LSF into their curricula, training the next generation of architects, engineers, and builders in this innovative technology.

At the same time, construction companies and manufacturers must continue to innovate, improving the efficiency, affordability, and accessibility of LSF systems. By working together, stakeholders can ensure that LSF becomes a mainstream solution, capable of addressing the world’s most pressing construction challenges.

A Call to Action

The construction industry is at a crossroads, facing increasing demands for sustainability, efficiency, and resilience. Lightweight Steel Framing (LSF) offers a clear path forward, combining cutting-edge technology with proven performance. Whether you’re planning a new build, renovating an existing structure, or exploring solutions for large-scale development, LSF provides a versatile and future-proof option.

As we look to the future, the adoption of LSF represents more than just a shift in building methods—it’s a commitment to a smarter, greener, and more sustainable way of living. By choosing LSF, we can create structures that not only meet the needs of today but also contribute to a better tomorrow. The time to embrace LSF is now, and the possibilities are limitless.

In Summary

Lightweight Steel Framing (LSF) is revolutionizing the construction industry, offering a blend of durability, efficiency, and sustainability that traditional methods simply cannot match. From its origins as an innovative alternative to wood framing to its current role as a global building solution, LSF has proven its value time and time again. As the world continues to evolve, LSF will remain at the forefront of construction innovation, helping to build a future that is stronger, smarter, and more sustainable for all.

LSF in the Era of Smart Cities and Digital Transformation

As urbanization accelerates and the concept of smart cities gains momentum, LSF is emerging as a key enabler of modern, technology-driven construction. Smart cities rely on efficient, scalable, and sustainable building solutions, and LSF fits seamlessly into this vision. Its lightweight and modular nature allows for easy integration with smart building systems, such as energy management, IoT-enabled devices, and automated controls. This synergy between LSF and smart technologies is paving the way for buildings that are not only structurally sound but also intelligent and responsive to the needs of their occupants.

LSF and Climate Resilience

Climate change is one of the most significant challenges of our time, and the construction industry must adapt to its impacts. LSF’s durability and resistance to extreme weather conditions make it an ideal choice for building climate-resilient structures. In areas prone to hurricanes, floods, or wildfires, LSF homes and buildings can provide a safer and more secure environment for communities. Additionally, the energy efficiency of LSF structures contributes to reducing greenhouse gas emissions, aligning with global climate goals.

Affordable Housing Solutions with LSF

The global affordable housing crisis is another area where LSF can make a substantial impact. Its cost-effectiveness and rapid construction capabilities make it an excellent solution for delivering high-quality, affordable housing at scale. Governments and NGOs around the world are increasingly turning to LSF to address housing shortages in urban and rural areas alike. By reducing construction costs and timelines, LSF enables more people to access safe and comfortable homes, improving quality of life and fostering economic development.

LSF in Industrial and Commercial Applications

Beyond residential construction, LSF is also transforming industrial and commercial building projects. Warehouses, office buildings, and retail spaces constructed with LSF benefit from its flexibility, allowing for open floor plans and customizable designs. The speed of construction is particularly advantageous for businesses looking to minimize downtime and quickly operationalize new facilities. Furthermore, the aesthetic versatility of LSF enables architects to create visually striking designs that meet both functional and aesthetic requirements.

The Role of Policy and Regulation

To fully realize the potential of LSF, supportive policies and regulations are essential. Governments can encourage the adoption of LSF by offering incentives for sustainable construction practices, updating building codes to accommodate modern methods, and investing in research and development. By creating an enabling environment, policymakers can accelerate the transition to more innovative and sustainable building practices.

A Vision for the Future

The future of construction is bright with LSF at its core. As the world continues to grapple with challenges like urbanization, climate change, and resource scarcity, LSF offers a practical and forward-thinking solution. Its ability to combine strength, efficiency, and sustainability makes it a cornerstone of modern construction, capable of meeting the diverse needs of a rapidly changing world.

Final Words

Lightweight Steel Framing (LSF) is more than just a building method—it’s a symbol of progress and innovation in the construction industry. By embracing LSF, we can create structures that are not only functional and durable but also environmentally responsible and socially impactful. As we move forward, LSF will continue to inspire new possibilities, shaping a built environment that is resilient, efficient, and sustainable for generations to come. The journey with LSF is just beginning, and its potential is boundless.

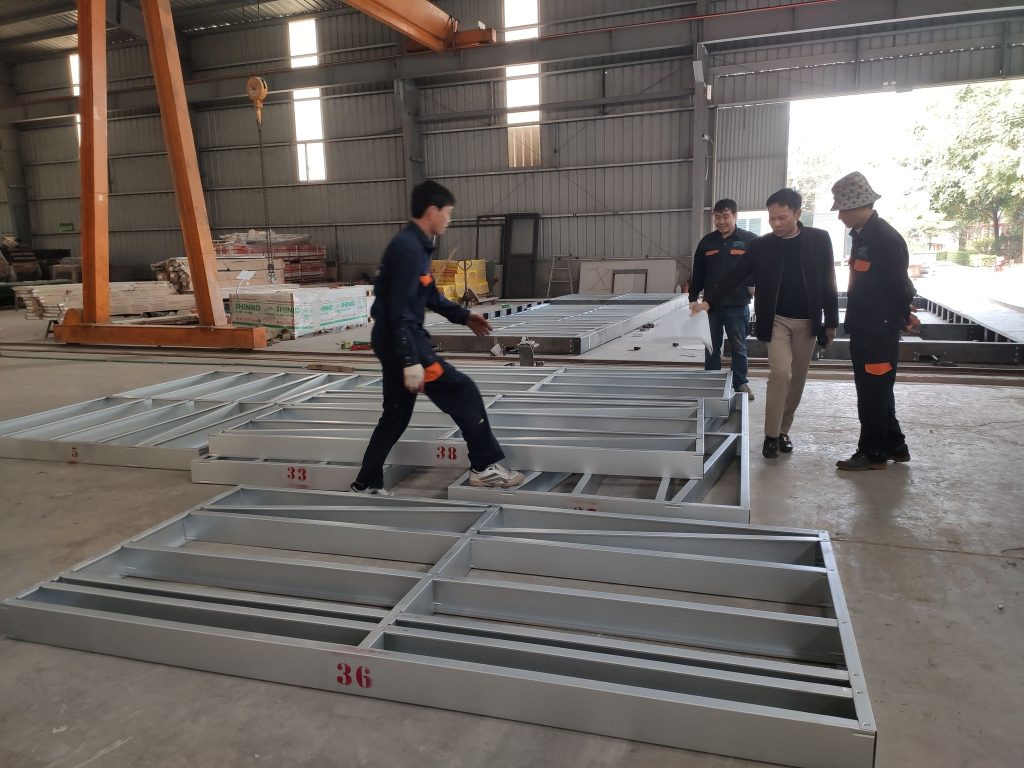

About Phu Nguyen Steel: A Trusted Light Steel Frame Supplier for Australian Projects

Phu Nguyen Steel is a leading manufacturer and supplier of light steel frames, specializing in the production of high-quality steel framing systems that meet international standards for export. With years of experience in the steel industry, Phu Nguyen Steel has earned a solid reputation for delivering durable, eco-friendly, and cost-effective steel frame solutions that cater to both domestic and international markets, including Australia.

Based in Vietnam, Phu Nguyen Steel has become a reliable partner for builders and contractors who need top-quality steel frames for a wide range of construction projects, from residential homes to large-scale commercial buildings. The company’s commitment to precision engineering, advanced manufacturing techniques, and stringent quality control procedures ensures that each steel frame product meets the highest standards of strength, safety, and performance.

Key Features of Phu Nguyen Steel’s Steel Frame Solutions

Why Choose Phu Nguyen Steel for Your Next Australian Project?

- Global Reach and Export Experience: Phu Nguyen Steel has successfully exported light steel frames to various countries, including Australia, making them an ideal choice for international construction projects. The company’s experience in navigating international shipping, customs clearance, and local regulations ensures that your steel frames arrive on time and in perfect condition.

- Commitment to Excellence: With a focus on quality, sustainability, and customer satisfaction, Phu Nguyen Steel continues to set the benchmark for steel frame manufacturing in the region. Whether you are a residential developer, commercial contractor, or industrial builder, Phu Nguyen Steel is equipped to provide you with the steel frame solutions that align with your project needs.

- Proven Track Record: Phu Nguyen Steel’s products have been used in numerous successful construction projects across different sectors, earning the trust of contractors and developers alike. Their steel frames are known for their durability, safety, and ability to withstand the test of time.

If you’re looking for a reliable and experienced supplier of light steel frames for your Australian construction project, Phu Nguyen Steel is the perfect partner to ensure the success of your build.

Why Australian Steel Frame Suppliers Like Phu Nguyen Steel Are the Best Choice for Your Next Project

In conclusion, whether you’re building in Australia or abroad, choosing the right steel frame supplier is essential to ensure the success and longevity of your construction project. Phu Nguyen Steel, as a leading manufacturer of high-quality light steel frames, stands out as a top choice for both Australian builders and international clients. With a focus on quality, sustainability, customization, and reliable delivery, Phu Nguyen Steel is the partner you need for your next project.

Their commitment to excellence and customer satisfaction, combined with their competitive pricing and strong international export capabilities, ensures that Phu Nguyen Steel is not just a supplier, but a long-term partner you can trust for all your steel framing needs.