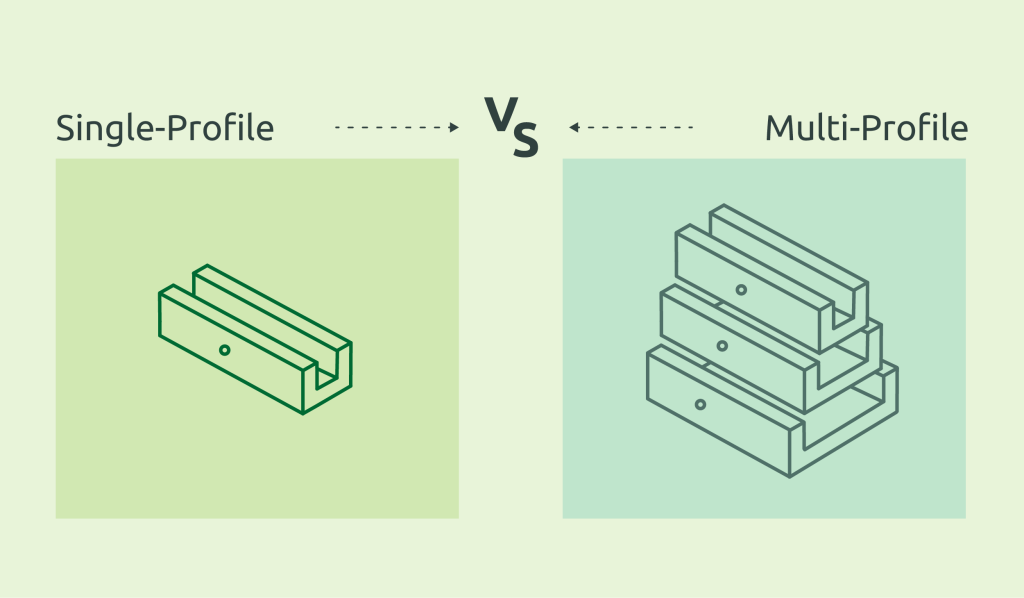

In the construction industry, steel roll forming machines are indispensable for producing cold-formed steel framing components. These components are essential in modern construction, offering structural integrity and design flexibility. Choosing between single-profile and multi-profile roll forming machines is a critical decision that impacts production needs, efficiency, and adaptability. Understanding the differences and benefits of each type of equipment will help manufacturers make the best choice for their operations.

MENU

Single Profile Roll Forming Machines

Single-profile steel roll forming machines are designed to produce one specific steel profile consistently. These machines are dedicated to a single setup, ensuring high production speeds and precision for that particular profile. The consistent output of single-profile machines makes them efficient and cost-effective, especially for large-scale production projects where the same profile is continuously required.

Benefits and Considerations of Single-Profile Machines

The primary benefits of single-profile roll forming machines include:

– High Production Efficiency: Thanks to their specialized setup and automated measurements, single-profile machines achieve high output with minimal downtime, as no adjustments are needed between jobs.

– Consistent Quality: The dedicated setup ensures that profiles are replicated with high quality.

– Low Maintenance Costs: Single-profile machines are easy to maintain, requiring fewer skilled workers and fewer replacement parts.

– Labor Requirements: Single-profile machines typically need only one operator. However, assembling specific components like floor joists may require more labor compared to larger profiles like Deep C joists.

– Integrated Production Process: With single-profile machines, manufacturers can produce entire structures, including forming, assembling, and installing steel frames without downtime. This efficiency reduces waiting times and keeps production schedules on track.

However, single-profile roll forming machines also have limitations:

– Limited Flexibility: These machines cannot adapt to different profiles, restricting their use to specific applications.

Multi-Profile Roll Forming Machines

Multi-profile roll forming machines are designed to handle various steel profiles within the same machine. These machines feature profile-changing mechanisms, allowing manufacturers to switch between different web widths, flange depths, and other profile variations. This flexibility makes multi-profile machines ideal for projects requiring multiple profile types and design changes.

Benefits and Considerations of Multi-Profile Machines

The main benefits of multi-profile roll forming machines include:

– Flexibility: These machines can produce a wide range of profiles, meeting diverse project requirements.

– Space Savings: Owning a multi-profile machine can save floor space equivalent to four single-profile machines, making it an ideal choice for manufacturers with limited space.

However, there are some considerations:

– Higher Initial Investment: Multi-profile machines come with a higher upfront cost.

– Complex Maintenance: These machines require skilled labor and more complex maintenance due to the number of components involved.

– Labor Requirements: Multi-profile machines typically need two people to change tools—a skilled operator and an assistant to change tools on the punching block. However, less labor is required when producing simpler profiles like Deep C joists.

– Segmented Production Process: With multi-profile machines, manufacturers must form all profiles of one type, then switch to another profile, and so on before assembling the frame. Typically, each profile is formed and stacked on a rack before later assembly. This segmentation leads to downtime and time pressure, which can be costly in construction where time is money.

Comparison: Single-Profile vs. Multi-Profile Machines

When comparing single-profile and multi-profile roll forming machines, several factors should be considered:

– Production Efficiency: Single-profile machines offer high output with minimal downtime, while multi-profile machines have significant downtime when changing profiles.

– Flexibility: Multi-profile machines provide greater flexibility in handling different profiles and design changes.

– Cost: Single-profile machines have lower operating and maintenance costs.

– Labor Requirements: Single-profile machines typically require fewer workers, while multi-profile machines need more labor to change profiles.

– Space Savings: Multi-profile machines can significantly save floor space by combining the capabilities of multiple single-profile machines into one unit.

– Scalability: Single-profile machines are suitable for large-scale, consistent production, while multi-profile machines are better suited for projects requiring a variety of profiles.

Choosing between single-profile and multi-profile roll forming machines depends on various factors, including production volume, project requirements, and long-term business goals. Single-profile machines are ideal for large-scale, consistent production, offering efficiency and cost savings. On the other hand, multi-profile machines provide flexibility and diversity, making them suitable for varied and customized projects. The additional benefit of space savings with multi-profile machines is also an important consideration for manufacturers with limited space. Manufacturers should carefully assess their specific needs and production goals to select the most suitable equipment for their operations.

Optimizing Your Roll Forming Operations

Once you’ve chosen the right roll forming machine for your business, the next step is to optimize your operations for maximum efficiency and profitability. Here are some actionable tips:

1. Invest in Training: Ensure your operators are well-trained to handle the specific machine type. Skilled operators can minimize downtime and maximize output.

2. Regular Maintenance: Schedule regular maintenance to keep your machines running smoothly. This is especially important for multi-profile machines, which have more complex components.

3. Streamline Workflow: Organize your production floor to minimize movement and reduce time spent on non-productive tasks. This is particularly beneficial for multi-profile machines, where profile changes can be time-consuming.

4. Leverage Technology: Consider integrating advanced software and automation tools to enhance precision and reduce manual errors.

5. Monitor Performance: Track key performance indicators (KPIs) such as production speed, downtime, and defect rates to identify areas for improvement.

By implementing these strategies, you can ensure that your roll forming operations are not only efficient but also adaptable to future challenges and opportunities. Whether you choose a single-profile or multi-profile machine, the key to success lies in aligning your equipment with your production goals and continuously optimizing your processes.

See more:

- Steel Frame House in Vietnam: The Ultimate Guide of Modern Construction 2025

- Steel Frames: The Critical Risks You Need to Consider in 2025

- Could Light Gauge Steel Framing be the pinnacle of innovation in offsite construction technology 2025?

- Light Steel Frame PN STEEL: Revolutionizing Modern Construction 2025

About Phu Nguyen Steel: A Trusted Light Steel Frame Supplier for Vietnam Projects

Phu Nguyen Steel is a leading manufacturer and supplier of light steel frames, specializing in the production of high-quality steel framing systems that meet international standards for export. With years of experience in the steel industry, Phu Nguyen Steel has earned a solid reputation for delivering durable, eco-friendly, and cost-effective steel frame solutions that cater to both domestic and international markets, including Australia.

Based in Vietnam, Phu Nguyen Steel has become a reliable partner for builders and contractors who need top-quality steel frames for a wide range of construction projects, from residential homes to large-scale commercial buildings. The company’s commitment to precision engineering, advanced manufacturing techniques, and stringent quality control procedures ensures that each steel frame product meets the highest standards of strength, safety, and performance.

Key Features of Phu Nguyen Steel’s Steel Frame Solutions:

- International Quality Standards: Phu Nguyen Steel’s products adhere to Australian and international construction standards, such as AS/NZS 4600 and ISO 9001, ensuring that the steel frames meet the requirements for both local and global markets.

- Customizable Steel Frame Systems: Understanding the unique needs of each project, Phu Nguyen Steel offers a range of customizable light steel frame solutions. From residential to commercial applications, the company can design and fabricate steel frames to suit your specific project requirements.

- Sustainable and Eco-Friendly Products: As part of its commitment to sustainability, Phu Nguyen Steel uses recycled materials in its manufacturing processes, ensuring minimal environmental impact. Steel is also fully recyclable, making it a sustainable choice for builders aiming to reduce their carbon footprint.

- Advanced Manufacturing and Delivery Capabilities: Phu Nguyen Steel uses state-of-the-art CNC machines and automated systems to produce steel frames with high precision and efficiency. The company is also equipped with robust logistics to handle both domestic and international deliveries, ensuring on-time product delivery for construction projects worldwide, including in Australia.

- Competitive Pricing: Phu Nguyen Steel provides cost-effective steel frame solutions without compromising on quality. By leveraging advanced manufacturing technologies and efficient production processes, the company offers competitive pricing that allows builders to maximize their project budgets.

- Technical Support and Expertise: In addition to providing high-quality products, Phu Nguyen Steel offers expert technical support, from the design phase to installation, ensuring that the steel frames are correctly integrated into your building project. This makes Phu Nguyen Steel a reliable partner for builders who require not only top-notch materials but also professional guidance throughout the construction process.

Why Choose Phu Nguyen Steel for Your Next Australian Project?

Global Reach and Export Experience: Phu Nguyen Steel has successfully exported light steel frames to various countries, including Australia, making them an ideal choice for international construction projects. The company’s experience in navigating international shipping, customs clearance, and local regulations ensures that your steel frames arrive on time and in perfect condition.

Commitment to Excellence: With a focus on quality, sustainability, and customer satisfaction, Phu Nguyen Steel continues to set the benchmark for steel frame manufacturing in the region. Whether you are a residential developer, commercial contractor, or industrial builder, Phu Nguyen Steel is equipped to provide you with the steel frame solutions that align with your project needs.

Proven Track Record: Phu Nguyen Steel’s products have been used in numerous successful construction projects across different sectors, earning the trust of contractors and developers alike. Their steel frames are known for their durability, safety, and ability to withstand the test of time.

If you’re looking for a reliable and experienced supplier of light steel frames for your Australian construction project, Phu Nguyen Steel is the perfect partner to ensure the success of your build.

Why Australian Steel Frame Suppliers Like Phu Nguyen Steel Are the Best Choice for Your Next Project

In conclusion, whether you’re building in Australia or abroad, choosing the right steel frame supplier is essential to ensure the success and longevity of your construction project. Phu Nguyen Steel, as a leading manufacturer of high-quality light steel frames, stands out as a top choice for both Australian builders and international clients. With a focus on quality, sustainability, customization, and reliable delivery, Phu Nguyen Steel is the partner you need for your next project.

Their commitment to excellence and customer satisfaction, combined with their competitive pricing and strong international export capabilities, ensures that Phu Nguyen Steel is not just a supplier, but a long-term partner you can trust for all your steel framing needs.